- Delivery time 3-4 working days

₹0

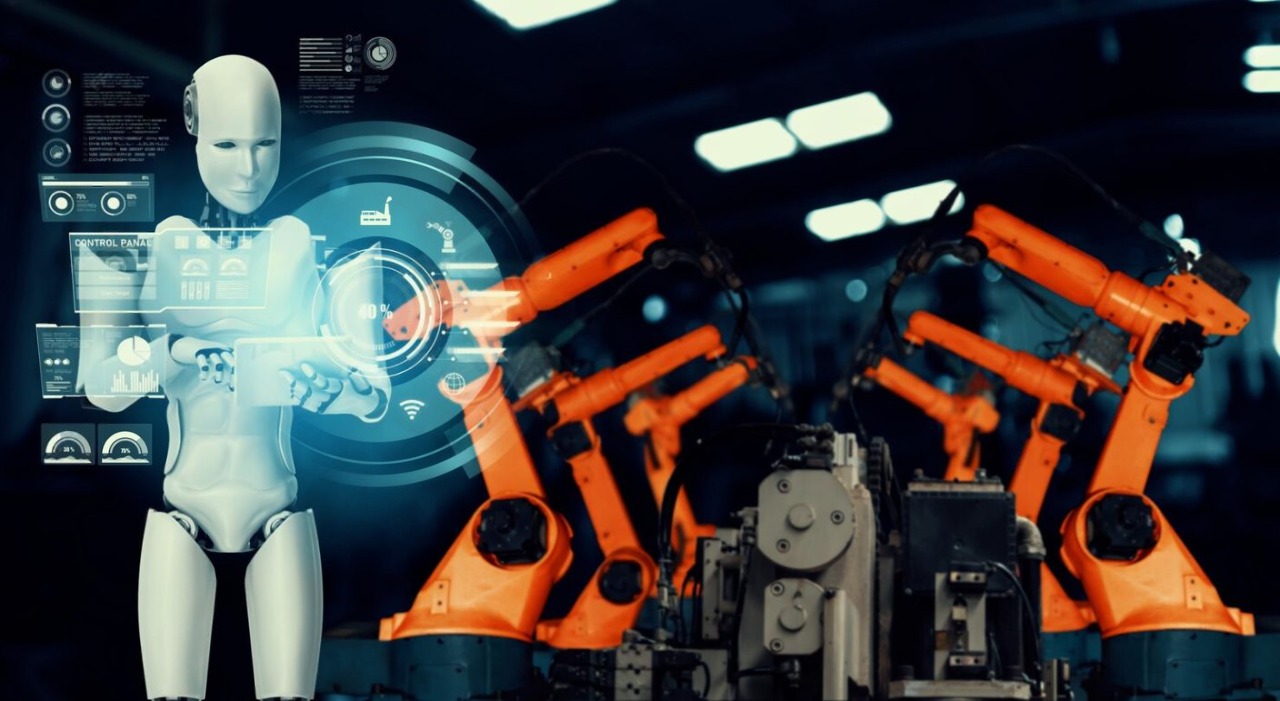

The Future of Manufacturing: Smart Machines and Automation

The manufacturing world is moving fast-faster than ever before. What used to take weeks or months is now being done in days. At the heart of this transformation are smart machines and automation, two forces that are reshaping how factories work, how products are made, and how businesses compete in a crowded global market.

A few decades ago, automation meant replacing simple, repetitive tasks with mechanical systems. Conveyor belts, robotic arms, and programmable machines handled basic duties with impressive consistency. But now, the game has changed. Machines are no longer just doing-they’re thinking, learning, and adapting. This evolution is turning traditional

manufacturing floors into smart factories.

Smart machines are built with sensors, software, and real-time data analytics. They don’t just perform tasks-they understand them. For example, a smart milling machine can detect when a blade is wearing out and alert the operator before a breakdown happens. This level of intelligence is making factories more efficient, reducing waste, and keeping downtime to a minimum.

Automation, too, has grown more powerful. It’s not just about speeding up production-it’s about refining it. Automated systems today can manage entire processes with minimal human input, from ordering materials to assembling components and packaging finished goods. These systems follow complex logic, make decisions on the fly, and even adjust themselves based on current workloads.

What makes this shift even more significant is how accessible it’s become. It’s no longer limited to huge corporations with massive budgets. Even small and mid-sized manufacturers are embracing smart technologies. With cloud-based systems and modular automation, businesses can start small and scale up gradually—making innovation within reach for everyone.

By mid-2025, many of these advances are no longer just early trends-they’re becoming the standard:

- Machines equipped with real-time analytics are boosting output while reducing erro rates.

- Robotics systems are handling more than just simple tasks-they’re managing workflows.

- AI-driven software is optimizing supply chains and predicting maintenance needs.

- Entire production lines are adjusting automatically based on demand fluctuations.

- Workers are partnering with machines in more collaborative, less hazardous ways.

One of the most exciting parts of this shift is how human roles are changing—not disappearing.

Smart factories still need smart people. But the focus is shifting. Instead of performing repetitive tasks, workers are supervising systems, analyzing data, and solving complex problems. It’s a shift from muscle to mindset.

Consider the rise of collaborative robots, or “cobots.” These machines work right next to humans, handling heavy lifting, precision work, or dangerous steps in the process. They’re designed to enhance what people do, not replace them. As a result, work environments are becoming safer, and employees can focus on more meaningful tasks.

Another game-changer is flexibility. Older manufacturing setups were rigid-you had to retool entire systems to make a different product. But with smart automation, adjustments can be made with a few keystrokes. A machine that was making one product in the morning can switch to a different one by the afternoon, based on customer demand or stock levels.

This adaptability is especially important in today’s fast-moving markets. Consumers expect personalized, high-quality products with quick delivery times. Smart manufacturing makes that possible. Businesses that can pivot quickly are winning more customers-and keeping them.

There’s also a deeper impact. Smarter manufacturing means less waste, better resource management, and lower energy use. Systems track exactly what’s being used and where. If a process is inefficient, it can be flagged and fixed. It’s better for the bottom line and better for the environment.

That said, there are challenges. New technologies require new skills. Companies need to invest not just in machines, but in training. Cybersecurity becomes a priority, too-more connected machines mean more risk if systems aren’t protected. But those who plan carefully are already seeing strong returns on their efforts.

In conclusion, the future of manufacturing isn’t just about faster production lines. It’s about smarter ones. Machines and automation are unlocking new levels of efficiency, precision, and flexibility. But perhaps most importantly, they’re creating an environment where people and technology work together-not against each other.

As we look ahead, it’s clear that manufacturers who embrace this change-who invest in intelligent systems and develop skilled, adaptable teams-will be the ones leading the way. The tools are already here. The future is in motion.

Need Help?

+91 9910257614

10:30 AM to 8:00 PM

- -5% for all order in this week Shop now

- Delivery time 3-4 working days